Tag Archives: Delaware

Process Measurement Variation. 2022 Best

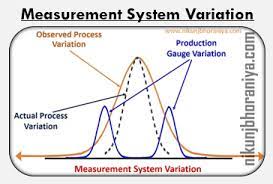

For this assignment we will focus on the following case Study: Understanding Process Measurement Variation. Introduction. For this assignment, you will conduct an experiment then create supporting visuals to be placed in a PowerPoint presentation of your findings.

Process Measurement Variation.

Introduction. For this assignment, you will conduct an experiment then create supporting visuals to be placed in a PowerPoint presentation of your findings. Your presentation should be easy to read and have a consistent design theme throughout. Please complete the first four chapters in the following LinkedIn Learning course on PowerPoint essentials before creating your presentation: PowerPoint2019 Essential Training. To help you learn about measurement variation, try this experiential learning exercise. (We are indebted to Alan Goodman, DuPont Company, Wilmington, Delaware, for bringing this exercise to our attention.)

Process Measurement Variation.

Scenario UPDATE: Due to COVID-19, students will NOT be collecting their own data for this assignment. Instead, your instructor will share the data sets with you. You have started a new business providing height measurements of humans. Your customers expect accurate and precise measurements. You offer two methods of measurement: a yardstick or meterstick, and a tape measure. You must test the two methods to evaluate their performance and provide the results to your customers. For this experiment, you will need the following: A yardstick or meterstick. A tape measure.

Process Measurement Variation.

Access to a single entrance door that is six feet or taller. Twenty or more individual participants. Instructions Method 1 You will test Method 1 in this way: Ask each participant to measure the height of the entrance door using the yardstick or the meterstick. The participant will report the measurement to you or someone you have designated as the data collector. If the participants are together, make sure that they don’t reveal their answers to anyone but the data collector. Tabulate the data and plot each measurement on a run or sequence chart. No deviation from the prescribed method is allowed.

Process Measurement Variation.

Method 2 For Method 2, you may use the same or a different set of participants and the same entrance door or another door. This time, the participants will use the tape measure in any way they desire. Again, each person silently reports the measurement of the door to you or a designated data collector. Tabulate and plot each data point as in Method 1. PowerPoint Presentation Create a PowerPoint presentation in which you complete the following: Compare the accuracy and precision of the two methods using graphical and analytical methods. Develop a flow chart for each method in which you specify the key problems that might be present.

Process Measurement Variation.

Develop the supplier, input, process steps, output, and customer (SIPOC) model to analyze the process of both methods. This may also be done in the flow chart. (Please reference these instructions on how to create a flow chart in Microsoft Word.) Identify the method that was most accurate. Provide a rationale for your response. Analyze the flow chart and SIPOC model to identify opportunity for improvement (OFI). Next, categorize whether the OFIs are caused by special causes or common causes variations. Provide a rationale for your response. Identify which method of measurement you would recommend. Explain why.

Process Measurement Variation.

Discuss whether different methods should be used under different circumstances. Consider the role of different customer segments. Discuss the feelings the participants experienced when using the two methods. Describe the differences between the two sets of feelings. Assess whether these differences are important. Provide a rationale. Use Basic Search: Strayer University Online Library to identify at least two quality references to support your discussion. https://youtu.be/wN7gVPns0-o